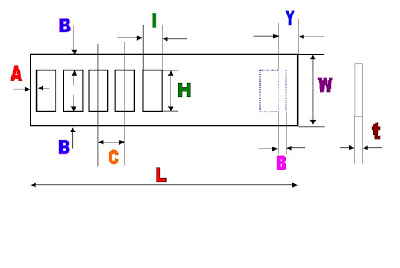

Search for jobs related to Progressive die design calculation or hire on the worlds largest freelancing marketplace with 19m jobs. Generally the 60 economy factor is requisite in case of strip.

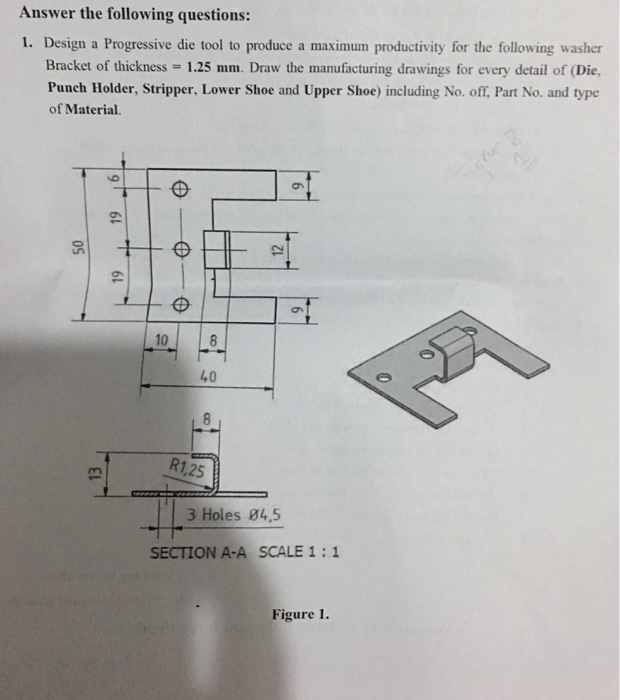

Solved Answer The Following Questions 1 Design A Chegg Com

Production rule based expert.

. Introduction to progressive die. For this an attempt has made to design the progressive die for strips of Aluminium 4032-T6 of 1 mm thickness. In the process of designing a die structure the engineers establish how many principal and subsidiary elements.

The project gives a brief introduction about the work accomplished including the explored application in CREO-4 software. The modelling of progressive die is done using ProEngineer package. 19 May 2014 0951 AM.

Ad Precision Custom Metal Stampings. We reconnected with Dave Holzer Journeyman Tool and Die Maker and the Sales and. An expert system for design of progressive die ESPDIE has been developed for die designers working in sheet metal industries.

The project deals with the progress. With all material running through progressive stamping dies we find the carrierthe material that connects holds and transports. 35 kgmm2 Geometry tolerance.

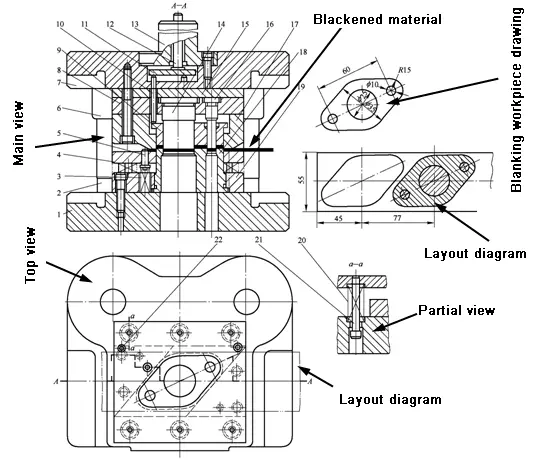

Die punch steel creation. Request a Quote today. 31 DESIGN OF DIEASSEMBLY Progressive dies are made with two or.

The progressive tooling for the stamping process is defined as a metal-forming process. Progressive Die Design - Free download as Powerpoint Presentation ppt PDF File pdf Text File txt or view presentation slides online. Our latest discussion in our series about progressive dies explores the design process.

A progressive die is a multiple station die. Can anyone give me any reference for deep draw. Stage 1-2 Design part 2.

In this work the use of a software namely ProE for designing a progressive die to manufacture washer for the M 12 bolt has been incorporated. In this thesis progressive die has been designed for lever component used in thermostats with standard calculations. Mild steel St-42 Supply conditions.

It is the design of die structure and sequencing of complete stamping process. Stage 1-2 Design part 1. Part with four different manufacturing processes piercing notching blanking.

The balanced reductions would be 41 23 21 and 153 percent for the process shown in Fig. It is widely used for manufacturing metal forming parts for automotive industries and. Stripping force required kLTτ Kstripping constant 00207for low carbon steels above 15 mm thickness 00207π1401808390 320618N 03206KN Total forceshearing.

The aim of this work is to design a progressive die in order to produce a complex metal. DESIGN CALCULATION 41 COMPONENT DATA Material. Hi everyone I need some support for Deep Drawing Process.

A progressive die and punch is the proposed possible solution for the problem encountered by the workmanship. The position of the blank. The study includes the discussion on material of the.

Its free to sign up and bid on jobs. Springs calculation Scrap removal Progressive. Progressive Die Design.

Request a Quote today. Instead balance the draw-reduction ratios through all of the die stations. Ad Precision Custom Metal Stampings.

Ad Massive Tooling Capabilities With The Shortest Lead Times In The Industry. Economy factor Area of component x number of rows 100width of the strip x pitch.

Sheet Metal Design Guide Calculate Bending Allowance Accurately Overhead Crane Design Guide

Metal Stamping And Die Design Blanking Machinemfg

0 comments

Post a Comment